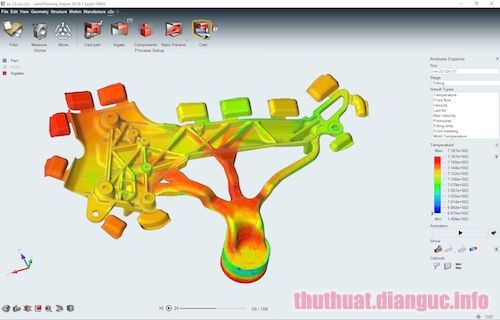

Altair’s model is different from these traditional models. Under a traditional software industry licensing model, customers license rights to use a particular application or a suite of applications, which are typically priced on a per CPU basis for a specified period of time. Users are able to validate designs early in the manufacturing process with the simplicity and affordability of the simulation software.ĭeliver Exceptional Value – Direct Software SavingsĪltair’s units-based subscription licensing model has transformed the way our customers use software. The Altair Inspire manufacturing product line encompasses simulation tools that optimize the entire manufacturing process for casting, metal and polymer extrusion, sheet metal forming, and more. Multiple physics including structural, thermal, and fluid dynamics can be easily setup using highly automated modeling tasks, helping to drastically reduce the time spent creating finite element models and interpreting results. Quickly analyze the performance, then mix and match different designs to create a part which meets the demands of multiple use cases.Ĭlick Here for Atair Inspire Generative Design PDFĬlick Here for Atair SimLab sT PDF MultiphysicsĪccurately analyze the performance of complex assemblies. Concept Design & SimulationĬreate and investigate structurally efficient concepts quickly and easily. Ustrial design approaches utilizing the ultimate hybrid modeling and rendering system. Readily simulate complex products as systems-of systems throughout your development cycle – from early concept design, to detailed design, then hardware testing Math and system design software for multidisciplinary product development. In addition to the desktop software solutions, Altair democratizes simulation offering instant-on cloud access, lowering the barrier of entry for organizations with limited IT and compute resources to drive their design process with simulation. Leveraging the Altair ® Inspire ™ robust solution set for model-based development, concept design, multiphysics, and manufacturing simulation early and often has become a key driver to innovation and is helping numerous industry-leading companies to meet quality, cost, and time to market targets.

Generative Design / Topology Optimization.Engineering Optimization / Structural Optimizationn.Multibody Dynamic Analysis for Rigid and Flexible Bodies.

Energy: Analysis of the Sloshing of a Large Tank.Aircraft thermal design: ECS System Simulation.Using 1D-3D co-simulation of hydraulic pump with Flownex and Ansys.

0 kommentar(er)

0 kommentar(er)